Beyond Disposal: Can You Recycle Perfume Bottles for Value Creation?

Table of Contents

1. Executive Summary

Luxury fragrance industry European Union PPWR. This report faces increasing pressure to circular due to environmental concerns and rules. This report examines the B2B value capacity in recycling glass perfumes, addressing the question: Can you recycle the perfume bottles effectively? We expand technical complications from various materials and contamination to advanced east-processing. The report designed closed loops (new bottles with recycled materials) and open-loop applications, proposed to the manufacturers, suppliers, retailers, and innovative B2B supply chain integration and collaboration models associated with waste management. It analyzes market dynamics, economic viability and scalability, emphasizes strategic investment and policy support. For B2B institutions, action is provided to enhance stability, reduce costs and run new product growth, actionable recommendations to imagine a circular future for the industry.

2. Introduction: Compulsory for circular in luxury packaging

The global luxury fragrance market, it is estimated to reach USD 716.6 billion by 2025, address its environmental footprint as the demand for consumer’s stability increases. “Can you recycle perfume bottles” is now a central strategic challenge.

Regulatory pressure, especially European Union’s packaging and packaging waste regulation (PPWR), mandate reduced waste, better design for recycling, and increase in recycling materials.

Glass, preferred for its luxury beauty and recurrence, presents challenges: delicateness, energy-intensive manufacturing, and diverse physical properties (colors, coatings, thickness, residual fragrance, components of non-eye-sheds). These complications require advanced recycling solutions to unlock B2B value, changing waste in resources and increasing brand stability.

3. Technical viability and glass perfume bottle recycling challenges

Receiving glass perfume bottles causes unique technical challenges due to their special design, which differ from standard container glass. High quality collants require addressing these complications.

3.1. Physical properties and their effects on recurment

The specialty of perfume bottles is:

- Different colors and coatings: Decorative coatings (eg, metalization, frosting) should be removed to prevent impurities or defects in new glass.

- Thickness and size: Thick, complex shapes crush and complicate sorting.

- Residual aroma: Organic residues require special removal for collet purity.

- Components of attached non-vocals: Plastic pumps, metal sprayers, caps and labels should be separated to prevent contamination.

Contamination from ceramic, stones, porcelain (CSP) and other ingredients leads to important landfilling. Cruducier is careful with the subsequent coated glass of the consumer due to external contamination concerns.

3.2. Collection Challenges: Post-Consumer vs. Industrial Waste Streams

The collection varies by source:

- Consumer waste: From homes, this stream is diverse and prone to contamination, require strong public systems, which is often supported by EPR or DRS programs.

- Industrial waste: From manufacturing, it is stream cleaner, but still requires separation, especially for coated glass.

Supply chain barriers exist in collecting collection, separation and quality standards.

Get Free Samples

3.3. Pre-proclamation techniques required for high quality Cullet

A multi-step pre-transmission approach is required:

3.3.1. Cleaning and contaminated removal:

Early sorting and crushed: waste glass is sorted and crushed into the crush (1-2 cm), which reduces the volume by 80%.

- Automatic sorting: Optical scanners, magnets, and A-in-operated systems (eg, egoglass, smartlands vision AI of doublesa) Rang Ai) Rang AI) removes separate glasses, metals, paper, plastic, and detect CSP contaminated substances with high accuracy.

- Removal of organic residues: wet cleaning, fluid bed dryer (aroma, adhesive), and testing removes organic residues and labels.

- D-coating technologies: Methods such as acidic or thermal de-koting are possible routes to remove decorative coatings.

3.3.2. Color sorting and purity:

- Color sorting: The glass is sorted with color because it cannot be replaced during recycling. Clere glass contains lower recycled material range (60%) than brown (70%) or green (90–95%). Low-covered Kallet (FE2O3 <500ppm) is important for luxury transparency.

- Libs Technology: Laser-inspired breakdown spectroscopy (Libs) provides a classification of real-time, highly accurate identification and waste, promising to the currents of complex glass, unaffected by sample properties.

- Cullet Sizing: Sieve machines separate separate accuses separately by particle size for different products.

3.3.3. Solvent recycling:

The onsite solvent for cleaning processes reduces operating costs and carbon footprints by reducing the use of recycling virgin solvent.

The entire process for efficiency and quality is rapidly automated.

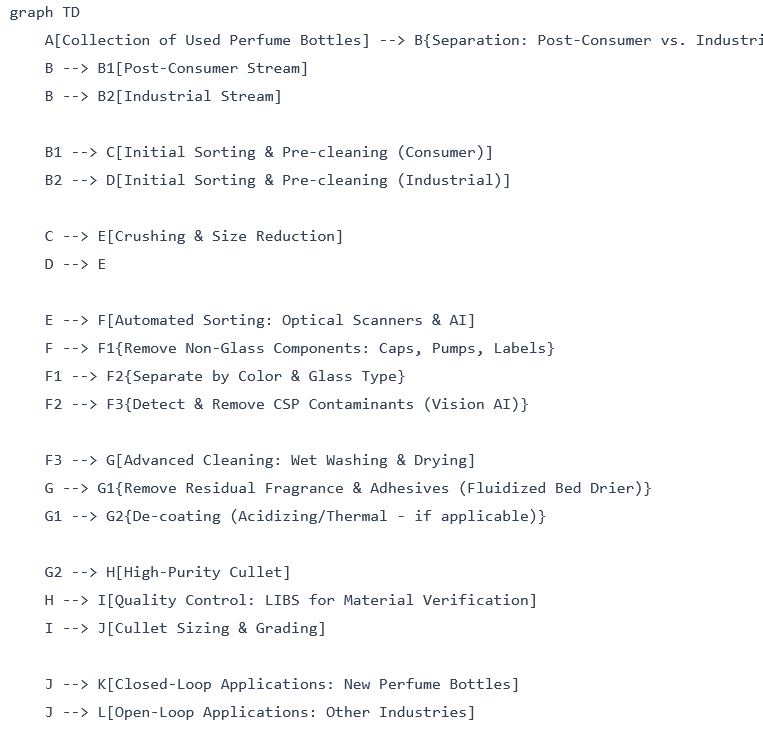

3.4. Technical Process Flow for Glass Perfume Bottle Recycling

This detailed process, with advanced sorting and cleaning, transforms complex glass perfume bottle waste into high-quality cullet for re-entry into the value chain.

4. Value Creation Pathways: Closed-Loop and Open-Loop Applications

Recycling glass perfume bottles creates economic and environmental value beyond waste diversion.

4.1. Closed-Loop Solutions: Manufacturing New Perfume Bottles with Recycled Content

The new luxury packaging directly aligns with recycling stability goals and consumer demand.

Brand Adoption: Luxury brand rapidly use consumer recycling (PCR) glass:

- Chanel (with Pochet Du Courval and Sibelco) used 15% domestic recycling glass for N ° 5 bottles, requiring innovative low-cousin crLLET sorting.

- Ralph Lauren Fragrances (l’oréal) refillable polo uses 20% PCR glass in the earth’s bottles.

- Issey Miyake Parfums used 5% PCR glass for drop D’SEY.

- Henry Rose uses 90% recycled glass daily.

- LVMH Beauty collaborates with bio-based/circular plastics, indicating extensive circular material commitment.

- Other brands such as Jean Paul Gaultier (55% recycled glass) and refillable system (Guerlen, Victor and Rolf) contribute.

Technical specifications and benefits:

- High-purity is important for luxury glass transparency and brightness.

- Recycled glass carbon reduces carbon footprint and energy consumption; The 10% increase in Cullet cuts 5% in CO2.

- Lightweight further saves material, transport and energy.

- PCR glass brands increase stability, appeal to environment consumed consumers (General Z, Millennials), and provide a unique marketing point.

Cost Savings and New Product Development:

- While the initial PCR packaging costs may be higher, long -term savings come from low virgin material dependence and price stability.

- This enables new permanent product lines, attracting a growing market section.

4.2. Open-Loop Applications: Integration into Other Industries

Processed Cullets, especially colored or mixed-color, can find high-value uses beyond luxury bottles. The global recycled glass market is estimated to reach USD 3 billion by 2033.

- Construction Zone: Cuttles take place in concrete, asphalt (“glasscret”), decorative elements (terrazo, countertops), construction materials, external plaster, and foam glass/ceramic mass.

- Insulation and fiberglass: recycled glass is a primary component for fiber filament insulation; US manufacturers used 4.1 billion pounds in 2019-2020.

- Decorative art and special glass products: functional art, mosaic tiles, synthetic marble, and suppressed materials replaced the material left in the glass.

- Landscaping and filtration: Used as mulch, on the way, biosals, fire pits, septic/water filtration, hydroponics, golf course sand trap and utility beds.

- Microbiids and abusive: processed and abrasive materials for reflective paints.

- Economic and Environmental Benefits:

- Cuttack waste, reduces the extraction of raw materials (saved from 1.2 tons per ton), and energy consumption (2.5–3% decrease for every 10% Cullet). The CO2 emission falls from 300 kg per tonnes of Cullet.

- Consumer garbage glass is cheaper than virgin materials.

- Mixed-colored glass, challenging for closed loops, can be safely melted for open-loop uses with color modifications.

By embracing both closed-loops and diverse open-loop applications, the luxury fragrance industry maximizes the value from the bottle of every vessel, actually promotes a circular economy.

5. B2B Supply Chain Integration and Stakeholder Collaboration Models

An effective recycling ecosystem for luxury glass packaging requires complex B2B integration and strong cooperation.

5.1. Importance of important roles and key B2B actors

Success rests on coordinated efforts:

- Perfume manufacturer (brand): Start the product life cycle, grab EPR, define the design, and manage life. Brands such as channels, Ralph Lauren, and LVMH integrate PCR glass and fund tech-back schemes.

- Packaging suppliers: (eg, Pochet du Courtwell, Zignago Wetro) create new bottles with recycled materials and innovate with designs, mono-materials and water-based adhesives for recycling.

- Luxury retailers: Critical collection points, take-back-back programs (eg, 15% discount of perfume shop) and educating consumers.

- Waste management companies and recycles: (eg, cibelco, strategic material ink.) Advanced collections, sorting, processing and cooling provide infrastructure for production, handling complex waste currents.

- Logistics provider: required for reverse logistics, to process the bottles used efficiently and adapt the cost to the manufacturers.

5.2. Innovative Collaboration Models and Reverse Logistics Strategies

Effective cooperation controls fragmentation.

- Tech-Back Scheme and Incentive:

- Brand-LED: Customers return by mail for bottles or encouragement (discount, points) at stores.

- Retailer-facility: Retailers host collection compartment (eg, Vioolia by Dubai Duties Free With Rickp).

- Third-party participation: collaborating with special recycles such as terracle for hard-to-recycle materials.

- Recommendation Integration: Extension of product life for objects with resale value.

- Reverse logistics optimization:

- Dedicated system: Separate reverse logistics system for efficiency.

- Re -purposable packaging: B2B reusable boxes for transportation.

- Digital Technologies: IOT sensor for real -time tracking, transparency and accountability, RFID, and blockchain.Integrated software (ERP) and future analytics optimize operations and forecast returns.

- Public-private partnership: Pilot program (eg, NAPA recycling, bold reuse) often rely on public-private cooperation and grant.

Get Free Samples

5.3. Addressing Regulatory Compliance

Compliance is important, governed by international, federal and local rules.

- Extended Manufacturers Responsibility (EPR): EPR schemes (eg, in Europe) justifies producers to encourage packaging lifestyle, funding infrastructure and sustainable design. EU PPWR is an important example.

- Packaging Minimalization: PPWR Article 9 mandate such as rules reduce packaging weight and volume.

- Design for recycling (DFR): The European Union is for DFR rules by 2025 released by 2027, which promotes easy-to-revolution packaging.

- Compliance Audit: Regular audit and risk assessment ensure obeying policies.

By promoting strong B2B partnership and taking advantage of advanced technologies, luxury aroma industry can build flexible, obedient reverse logistics systems, converting waste into value and circular.

6. Market mobility, economic viability and scalability ideas

Glass perfume bottle depends on the recycling’s successful scaling market dynamics, economic viability and scalability.

6.1. Market mobility and economic drivers/obstacles

The global recycled glass market is strong, it is estimated to reach USD 3 billion by 2033, inspired by the demand and rules of stability.

- Economic Driver:

- Cost Savings: Cuttack waste, reduces the extraction of raw materials and energy (to melt 10% less virgin)).

- Brand reputation/consumer demand: Permanent packaging enhances brand image and appeals to the environment consumed consumers (General Z, Millennials).

- Regulatory push: EU PPWR targets and EPR plans make strong market bridges and funding for recycled glass.

- New product opportunities: recycling enables new product lines in closed-loop and open-loop applications.

- Economic obstacles:

- Capital/Operations Expenditure: Important Investment in Advanced sorting, cleaning and processing machinery, high operating costs for labor, energy and transport.

- Contamination cost: contamination in single-stream systems increases the processing cost and reduces the Cullet price. Virgin material value volatility: fluctuations can affect the competition of recycled coulett.

- Recycling vs. New Production Cost: For custom bottles, reuse/recycling can sometimes exceed the new production cost.

6.2. Regional variations, infrastructure and regulatory structure

Scalability varies regionally:

- Global inequalities: Glass recycling rates vary widely (eg, Europe> 85%, US ~ 30%).

- Infrastructure: Well -developed waste management, advanced MRF, and dedicated glass recycling features are important.

- Regulatory framework: Strong EPR and DRS policies lead to high recycling rates and quality.

6.3. Investment Required and Market Demand for Recycled Content

- Investment: Initial investment for recycling businesses ranges from $ 250,000- $ 750,000 to advanced sorting (LIBS, AI), de-coating, and significant capex for commissioner.

- Market demand: Luxury (eg, using PCR glass using the channel, Ralph Lauren) and the increasing demand for high-quality collets in broad markets (construction, insulation) provides strong demand.

6.4. Scalability from local pilots to global programs

Scaling requires a multicolored approach:

- Scale economies: efficient collections, customized processing, and long-term end-user contracts reduce per-unit costs.

- Technical adoption: Great use of advanced pruning (AI, LIBS) and cleanliness is necessary.

- Standardization/DFR: Applying DFR principles to components (eg, removable cap) improves the scale on the scale.

- Public-private partnership: Important for the development and expansion of infrastructure.

- Consistent Regulations: International cooperation on EPR and recycling goals offers border scalability.

- Consumer involvement: Education and convenient take-back increase the amount of technology content.

The economic viability of luxury glass perfume bottle recycling is complex, but strategic investment, B2B cooperation, and supporting rules can unlock the important value and achieve large -scale circular.

Get Free Samples

7. Strategic Recommendations and Future Outlook

Infection in a circular economy for luxury glass perfume bottles provides immense opportunities. B2B institutions require a multi-dimensional strategic approach.

7.1. Actionable recommendations for B2B institutions

1.Policy advocacy and engagement:

- Lobby for IP security: Continue lobbying for discounts for IP-protected designs from standardization (eg, European Union PPWR).

- Support EPR plans: Participate in EPR plans to reproduce funding and durable design and participate in EPR schemes.

- Coordination Regulations: Work with industry and governments for frequent global recycling standards.

2.Technology Adoption and Investment:

- Invest in advanced sorting: Priority to AI-Integrated Optical Sorting (Picwissa, Smartands) and Leibas for accurate separation and contaminated removal.

- Develop de-coating solutions: Fund R&D for scalable de-coating technologies (aciding, thermal).

- Adapt to cleaning: Apply solvent recycling for advanced wet washing, fluid bed dryers, and residual fragrances and adhesives.

- Embrace digital traceability: Integrate IOT, RFID and blockchain for real -time tracking, reverse logistics efficiency and transparency.

3.Partnership Development and Cooperation:

- Cross-Industry Alliance: Waste management for integrated ecosystems, special recurrence (terrachael), forge partnership with packaging suppliers and competitors.

- Retailer Cooperation: Install a strong tech-back program with luxury retailers, offer encouragement (discount, loyal points).

- Reverse Logistics Specialization: Participated with special logistics providers to optimize the collection and reduce costs.

- Open Loop Market Development: Cooperate with construction, decorative art and insulation industries, which to expand the markets to not meet closed-loop standards.

4.Consumer engagement strategies:

- Clear communication: Provide clear instructions to prepare and return bottles, including separation of non-vicious components.

- Encourage participation: Apply attractive programs (discounts, awards, charitable donations).

- Highlight the environmental impact: transparently cut CO2 and communicate resource savings.

- Educate on circularity: Emphasize how participation expands physical life and reduces waste.

- Leverage digital platforms: Use websites, social media and AR to promote programs and educate consumers.

7.2. Future Outlook and Emerging Trends

The luxury fragrance industry is moving towards complete circular, powered by innovation and developed values.

- Disruptive technologies:

- Advanced AI/Robotics: more accurate, automatic pruning for complex packaging and minute contributor.

- Chemical recycling for coatings: Research in chemical methods for stubborn coatings.

- Modular recycling features: Mobile, modular assets (eg, O-I’s Mogra) may decently processing and reduce transportation.

- Bio-based/circular materials: Integration of bio-based and circular plastic (LVMH-Dow cooperation) for multi-material circular ecosystems.

- Long -term effects of circularity:

- Increased brand flexibility: circular models create flexibility against supply chain disruption and value volatility.

- New Business Model: Refillable System, Recommendation and Rise of Product-A-Service Model.

- Continuous competitive advantage: Circularity becomes a major discrimination, which attracts environment-conscious luxury consumers.

- Low environmental footprint: Global stability, contributing to the goals, reduces the footprint of the industry significantly.

- Innovation in design: Packaging designed for disassem, reuse, and recycling promotes a new era of durable luxury.

In fact, a spherical luxury fragrance industry trip, where every Vesseluxe bottle is a valuable resource, is complex but achievable.Innovation, B2B cooperation, and consumer engagement, the industry can redefine luxury for the 21st century.

Comments

Product Categories

Hot Sale Bottles

Unlocking Brand Identity Through Custom Perfume Bottles Wholesale with Vesseluxe

Unlock your brand’s unique identity with Vesseluxe’s custom perfume bottles wholesale solutions.

Why More Brands Are Choosing Custom Perfume Bottles

Discover why more brands are choosing custom perfume bottles to enhance brand identity, drive sales, and embrace sustainability.

2025 Global Trends in Luxury Cosmetic Packaging Wholesale

Luxury cosmetic packaging wholesale solutions with custom design, premium materials, and bulk supply for beauty brands, retailers, and OEM partners.

Stylish Glass Cosmetics Packaging Wholesale Options

Discover stylish glass cosmetic packaging wholesale options. Ideal for B2B buyers seeking premium, eco-friendly cosmetic packaging for beauty brands.

How Long Can Perfume Last in the Bottle: Factors Influencing Perfume Shelf Life

Discover how long can perfume last in the bottle. Learn how chemistry, storage, and packaging affect the integrity of a scent, and how to maximize the life of your fragrance.

- +86 186 5178 1159

- [email protected]

- Mon-Sun 07:00-21:00

Tags

The Strategic Advantage of Partnering with a Glass Roller Bottles Wholesaler for Premium Beauty Brands

Learn how a leading glass roller bottles wholesaler delivers high-quality, sustainable, custom packaging with strong formula protection and global compliance.

Case Study: How us Helped a Glass Perfume Bottles Wholesaler to Overcome Customization Challenges

Learn how a glass perfume bottles wholesaler in the UK partnered with us to overcome customization challenges and brand-aligned perfume bottles on time.

Guide for Glass Dropper Bottles Wholesaler: Design, Materials, and Compliance

Essential insights for a glass dropper bottles wholesaler on design, materials, and compliance for pharma, cosmetic, and lab applications.

Case Study: How A Glass Roller Bottles Vendor Supported a U.S. Partner with Custom Essential Oil Bottles

Learn how US helped a U.S. glass roller bottles vendor overcome customization challenges , brand-aligned essential oil roller bottles on time.