2.2. Schlüsselpunkte der technischen Materialien:

Inhaltsverzeichnis

Einleitung

You have to see whether it is durable and has a good texture. The appearance and resistance to manufacturing cannot be lost~ maßgeschneiderte Parfümflaschen Black technology blessing:

smart materials, AR interaction, RFID Chips can be put on the bottle, and even LED lights can be added, and 3D printing can be used to make customized textures, so that the bottle is not just a container, but also an “interactive” work of art~

Gratisproben erhalten

In the mass production of custom perfume bottles, there are many things to consider, such as minimum order quantity, mold cost, production cycle and supplier selection, which are all real challenges~

3.1. Things about minimum order quantity (MOQ) and cost Parfümflaschen custom glass bottles usually have a high minimum order quantity, which is often more than 10,000 yuan. For example, the minimum order quantity of custom bottles from Verallia in the UK is 30,000 yuan, and ordinary glass bottles are generally between 3,000 and 50,000 yuan. This is mainly because mold making is too expensive. A set of custom molds may cost 50,000 to 100,000 yuan or even higher, while a standard size mold is only 3,800 to 4,500 US dollars.

Differences in minimum order quantities for different materials:

The minimum order quantity for crystal glass bottles is relatively low, about 2,000 pieces can be made; but if the bottle weighs less than 30 grams, the minimum order quantity may soar to 500,000 yuan, which is exaggerated.

- The difference between spot and customized: The minimum order quantity for ready-made bottles is very low, about 1,000 pieces, but if you add customized colors, do surface treatment or change the shape, the minimum order quantity will increase. In order to spread the mold cost, suppliers will naturally require a higher minimum order quantity, and glass factories also prefer stable large orders.

- 3.2. Time-consuming and challenges in production It takes a long time to open the mold:

- It takes 12-16 weeks to make the mold alone, and the whole process from confirming the design to completing the production takes 50-60 days. The benefits of a high minimum order quantity:

- Although the high minimum order quantity looks scary, for manufacturers, a large quantity can reduce production risks and buffer unexpected losses. 3.3. Tips to reduce the minimum order quantity

Test the water with spot first:

At the beginning, you can use ready-made bottles to test the market reaction to avoid spending a lot of money on customization right away.

Use sample molds to see the effect:

It costs about $1,500 to make a glass sample mold, and it can be done in 35 days; acrylic molds are cheaper, $650 and 12 days, first take the sample mold to see if the design is okay.

Try crystal glass:

If the budget allows, choosing crystal glass can reduce the minimum order quantity~

- Find Chinese factories for OEM: Domestic production is very cost-effective, the mold opening cost may be only one-tenth of that in Europe and the United States, and the minimum order quantity can also be negotiated low (for example, 20,000), and if it is filled locally, it can save 20% of the cost.

- Material: Laser printing is very cost-effective, with a single cost of only $0.15.

- Dekoration: Find knowledgeable suppliers:

- Try to cooperate with suppliers who are familiar with various types of glass bottle products, they know better how to avoid pitfalls. Domestic production concentration:

Guangzhou, Foshan, and Xuzhou are the main production places for domestic cosmetic bottles, and the supply chain is mature.

- Large factories have more stable quality control: Large factories have large production scales, and quality stability is more guaranteed.

- In short, when planning the mass production of custom perfume bottles, you need to understand the minimum order quantity and mold cost to make a reliable budget and plan. 4. Design strategy to maximize visual impact

When customizing perfume bottles, design is the core of creating visual impact. You have to understand the design ingenuity, innovative technology and materials~ - 4.1. "Eye-catching code" in design good-looking design can directly poke the desire to buy, which can not only enhance the style of perfume, but also “write” the brand temperament on the bottle.

Gratisproben erhalten

the first time customers contact the product is to look at the packaging. At this time, the design must “spoil” the soul of the perfume in advance and rely on appearance to catch the eye first.

Tell a story with design:

custom bottles must be able to “speak”, hiding the inspiration source of the perfume and the feeling they want to convey in the shape.

- Emotional resonance is king: everyone will be attracted by bottles that match their own aesthetics. Creative designs can evoke emotions at once, and sales will naturally increase~

- The little tricks of color and shape: color can poke emotions (such as pink romance, black advanced), the lines of the bottle are also exquisite (angles are modern, curves are retro), and the geometric shape has a sense of refinement.

- The unboxing experience is super important: magnetic seals and layered compartments can make customers feel happy when unpacking, just like unpacking gifts, which is a multi-sensory experience~

4.2. Black technology and new materials to assist

- Material cross-border: In addition to ordinary glass, borosilicate glass, bioplastics, recycled glass, and even metals and ceramics can be used for innovation~

- Surface treatment: metallic luster, gradient coating, color-changing thermochromic materials, furry flocking, soft skin-friendly coating, make the bottle high-end in minutes~

Molding and modeling technology: CNC processing, 3D modeling and other technologies are used to make complex shapes, and bionic design and pressure blowing can also make the bottle more unique~

- Bottle caps are innovative: bamboo and recycled materials are used to make environmentally friendly bottle caps. Magnetic caps and weighted caps are both practical and memorable~

- Add technology buff: AR interaction, RFID chips, LED lights, etc. can all be put on the bottle, 3D Printing can also make customized textures, so that the bottle is not just a container~

- 4.3. Keep up with the design trend and avoid stepping on thunder Geometric style is popular:

- diamond-cut, angular bottles are super design~ Bold color matching:

- jump out of the conventional color system, use bold colors to echo the personality of the perfume~ Minimalism is high-end:

glossy and simple design, relying on texture to support luxury~

- Retro is back: combining nostalgic elements with modern aesthetics, retro and fashionable~

- engraving, changing color, adding QR code, make each bottle unique~ Environmental protection is hard currency:

- using recycled materials and degradable packaging, customer favorability is directly maxed out~ Understand these design routines, innovative technologies and materials, and the custom perfume bottles you make will definitely be able to kill blood in B2B wholesale and make customers fall in love with them at first sight!

5. Supplier identification and evaluation

In the project of custom perfume bottles, choosing the right supplier is the key to success or failure. You need to use a comprehensive set of standards and processes to carefully select them~

5.1. "Hard-core" standards for supplier evaluation

Raw materials must be reliable:

- Äußerlichkeit ist Gerechtigkeit: Melting and molding are technical jobs:

- the temperature must be precisely controlled when the glass is melted, otherwise it will affect the flow and wall thickness; the quality of the mold is the core during molding, the pressure-blowing method can make the shape more precise, and the bubbles must be “refined” out~ Annealing treatment cannot be omitted:

- the glass must be slowly cooled after molding to eliminate the internal stress, so that the bottle is strong enough~ Quality control must be as strict as a “detective”:

- each production link must be inspected with the naked eye, and then the size and defects (such as bubbles, cracks, scratches, etc.) must be measured with automated equipment; the surface of the bottleneck must be flat, otherwise it will affect the sealing; a pressure test must be performed, according to AQL Standard sampling, traceability through mold number~ Customized design requires communication:

- only handmade molds can make unique shapes, and the minimum order quantity requirements must be paid attention to; AI design may not meet production specifications, and it must be confirmed repeatedly with the manufacturer; details such as embossed textures must also be communicated in advance~ Sample testing is essential:

- let the supplier make pre-production samples first, and then batch them if there are no problems with trial production; samples can be used to demonstrate and test the effect~ 5.2. Use the scoring table to scientifically select suppliers

You can make a detailed evaluation list based on the above standards, and score from dimensions such as production capacity, quality control level, environmental protection measures, communication efficiency, and cost. Use data to speak, so that you can choose the most suitable supplier for custom perfume bottles~

- 6. Project Execution: Schedule, Logistics and Quality Assurance It is not easy to implement the design of a custom perfume bottle. Time planning, logistics arrangements and quality control must be clearly arranged~

- 6.1. Production Schedule: Each stage is a "highlight" The duration of the entire process depends on the complexity of the design and the customization requirements, as well as the efficiency of the supplier. The key stages must be closely monitored:

Design to Prototyping: - From concept formation to sample production, it can take a few weeks or a few months. In the middle, the details must be repeatedly adjusted with the sample mold~ Mold making:

- This is a time-consuming job, usually taking 12-16 weeks to complete~ Material procurement:

You have to find high-quality raw materials, and it would be even better if you can do environmentally friendly procurement; each batch of materials must be traceable, and pollution and dilution tests must be done~

- Mass production: Glass bottle molding, annealing, and preliminary inspection, this set usually takes 50-60 Day~

- Decoration processing: Printing, coating, engraving and other processes must be arranged. If it is an organic-shaped bottle, multiple rounds of polishing may be required~

- Assembly and quality inspection: Install parts such as bottle caps and pump heads, and then conduct a comprehensive inspection of the finished product~

- Packaging and transportation: E ach bottle must be individually wrapped and placed in a customized box, and then arranged for delivery~

- Personalisierte Anpassung: Choose the right transportation method:

- Choose sea, air or land transportation according to the urgency of time, cost and quantity of goods~ The packaging should be durable:

Use strong materials to pack to reduce damage during transportation~

Gratisproben erhalten

Prepare all documents in advance to avoid being stuck at customs~

Inventory management:

Coordinate production and delivery time, and don’t let inventory backlog or out of stock~

- 6.3. Quality assurance: High standards can produce good products Raw material control:

- All materials entering the factory must be strictly tested, and unqualified ones must not be used~ Keep a close eye on the production process:

- Quality control must be done at every link, such as GMP Standardization, automated mixing, and filling line disinfection are all necessary, and it is best to have independent quality control personnel to manage them~ Full inspection of finished products:

- Basic inspection: visually check for defects, measure weight, spray effect, and drop resistance~

- Professional testing: perform chemical resistance and leakage tests, and also measure internal stress and spray pattern consistency~

- Environmental simulation: perform temperature cycle and vibration tests to see if there will be any problems during transportation~

Follow industry standards:

keep records according to IFRA’s recommendations, and samples must be uniquely marked and properly stored~

Supplier management:

give priority to suppliers with ISO 9001 and other certifications, or find a third-party agency for independent quality inspection~

As long as the execution details of these projects are planned well, coupled with strict quality assurance measures, you can successfully deliver custom perfume bottles that meet the high requirements of the brand~

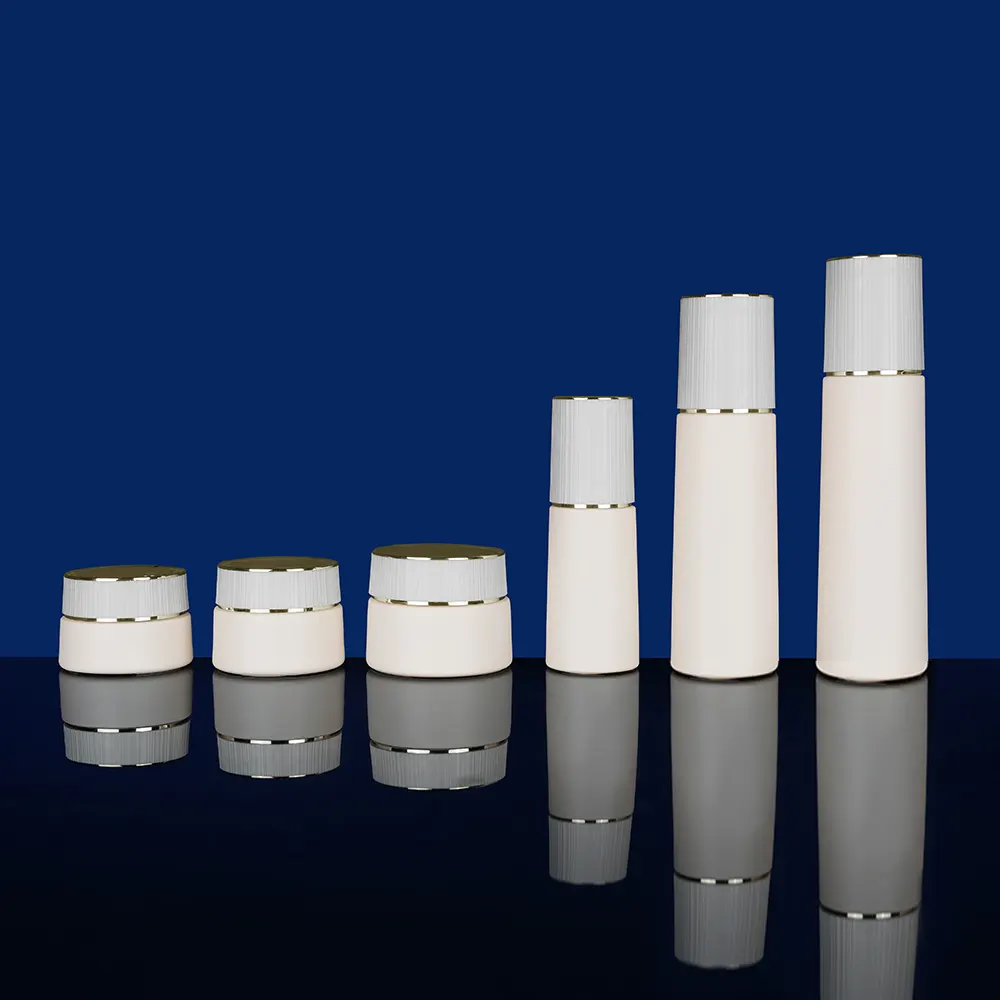

5g 10g 20g 30g Cosmetic Jars with Lids – Custom Empty Cosmetic Containers Wholesale

- 100ml Custom Luxury Crystal Perfume Bottle Wholesale Von der Konzeptbildung bis zur Stichprobenproduktion kann es einige Wochen oder einige Monate dauern. In der Mitte müssen die Details mit dem Stichprobenmodell wiederholt angepasst werden~

- Formenherstellung: Dies ist eine zeitaufwendige Tätigkeit, die normalerweise 12-16 Wochen dauert, um abgeschlossen zu werden~

- Materialbeschaffung: Sie müssen hochwertige Rohstoffe finden, und es wäre besser, wenn Sie umweltfreundliche Beschaffung durchführen könnten; jeder Charge von Materialien muss nachverfolgbar sein, und Schadstoff- und Verdünnungstests müssen durchgeführt werden~

- Massenproduktion: Glasflaschenformung, Glühen und vorläufige Inspektion, dieses Set dauert normalerweise 50-60 Tage~

- Dekorationsverarbeitung: Druck, Beschichtung, Gravur und andere Prozesse müssen geplant werden. Wenn es sich um eine organische Formflasche handelt, könnten mehrere Runden der Politur erforderlich sein~

- Montage und Qualitätsinspektion: Installieren Sie Teile wie Flaschenverschläge und Pumpenköpfe und führen Sie dann eine umfassende Inspektion des Endprodukts durch~

- Verpackung und Versand:Jede Flasche muss einzeln verpackt und in eine maßgefertigte Schachtel gelegt werden, bevor sie für den Versand vorbereitet wird~

6.2. Logistikplanung: Pünktliche Anreise ist wichtig

- Wählen Sie den richtigen Transportweg: Wählen Sie Seefahrt, Luft- oder Landverkehr entsprechend der Dringlichkeit, Kosten und Menge der Waren~

- Die Verpackung sollte langlebig sein: Verwenden Sie starke Materialien, um den Schaden während des Transports zu reduzieren~

- Verzögern Sie nicht die Zollabfertigung: Bereiten Sie alle Dokumente im Voraus vor, um an der Zollabfertigung festhängen zu vermeiden~

- Inventarverwaltung: Koordinieren Sie die Produktion und Lieferzeit, und lassen Sie das Inventar nicht zurückbleiben oder ausverkauft werden~

Gratisproben erhalten

6.3. Qualitätsassurance: Hohe Standards können gute Produkte produzieren

- Rohmaterialkontrolle: Alle Materialien, die in die Fabrik kommen, müssen streng getestet werden, und nicht qualifizierte Materialien dürfen nicht verwendet werden~

- Wachen Sie genau auf den Produktionsprozess: Die Qualitätssicherung muss an jedem Schritt erfolgen, wie z. B. GMP-Standardisierung, automatisierte Mischung und Desinfektion der Füllanlage, die alle notwendig sind, und es ist am besten, unabhängige Qualitätssicherungsmitarbeiter zu haben, die sie verwalten~

- Umfassende Inspektion der Endprodukte:

Grundinspektion: visuell auf Mängel überprüfen, Gewicht messen, Spray-Effekt und Abriebfestigkeit prüfen~

Professionelles Testing: Durchführen chemischer Widerstandstests und Lecktests, messen Sie innere Spannungen und die Konsistenz des Spraymusters~

Umgebungs Simulation: Durchführen von Temperaturzyklus- und Vibrationstests, um zu sehen, ob während der Transporte Probleme auftreten~

Nach Industriestandards: Führen Sie Aufzeichnungen gemäß den Empfehlungen der IFRA durch, und Proben müssen eindeutig markiert und korrekt gelagert werden~

Lieferantenmanagement: Priorisieren Sie Lieferanten mit ISO 9001 und anderen Zertifikaten, oder finden Sie ein Drittunternehmen für unabhängige Qualitätsprüfung~

Solange die Ausführungsdetails dieser Projekte gut geplant sind, gekoppelt mit strengen Qualitätsassurance-Maßnahmen, können Sie erfolgreich maßgefertigte Parfümflaschen liefern, die den hohen Anforderungen des Marktes entsprechen~

Wie

Produktkategorien

Top-Angebote Flaschen

Fallstudie: Maßgeschneiderte Glas-Lotionflaschen für ein japanisches Unternehmen

Entdecken Sie unser Projekt mit einer japanischen Marke für Glas-Lotionflaschen, zugeschnitten für B2B-Sourcing, große Mengenlieferungen und Premium-Kosmetiklösungen.

Fallstudie: Maßgeschneiderte ätherische Ölbürstlingflaschen für ein britisches Unternehmen

Maßgefertigte flüssigkeitsgebundene Ölbottchen mit UV-Schutzglaseinhausung gewährleisten Schutz des Produkts und Premium

Wie man die besten Roll-on-Parfümbehälter für Ihre Produktlinie wählt

Roll-on-Parfümbehälter sind eine ausgezeichnete Wahl für die Duftanwendung, bieten Präzision und Benutzerfreundlichkeit.

Fallstudie: Maßgeschneiderte Essentielle Flaschen mit Pipette für ein kanadisches Unternehmen

Maßgeschneiderte Essentielle Flaschen mit Pipette, präzise Mäntel und hochwertige Lösungen für Wellness-Unternehmen.

Parfüm-Haltbarkeit: Wie lange kann Parfüm in der Flasche halten

Entdecken Sie, wie lange Parfüm in der Flasche hält und wie primäre Verpackung durch Materialwissenschaft, Design und Lagerung die Haltbarkeit bewahrt.

- +86 186 5178 1159

- [email protected]

- Mo-So 07:00-21:00

Schlagworte

Case Study: Custom Engraved Perfume Bottles for Swiss Clients

custom engraved perfume bottles crafted with precision—consistent depth, sharp detail, and flawless

Eye Serums:

Allow direct application without spreading bacteria, popular for ease of use and travel.

Specific production lead time from international suppliers, especially in China, usually ranges from 15 to 35 days after sample approval, except for international shipping time. The sample time is short, usually 2 to 10 days. This is rapidly contradictory with domestic suppliers such as SKS Bottle & Packaging (USA), which orders for a business day, or Ampulla (UK). Foreign suppliers vs. rapid turnarounds and reduced inventory holding costs from local providers.

To reduce supply chain risks, including potential reduction and quality anomalies, startups should cultivate relationships with many suppliers. Diversification for both essential oils and packaging components enhances operating flexibility.

Case Study: Customized Bottle of Essential Oil for California Clients

Discover how Vesseluxe created custom bottle of essential oil balancing UV protection and elegance