L'avenir des flacons d'huile essentielle respectueux de l'environnement

Table des matières

Le marché des huiles essentielles connaît une croissance fulgurante. Pourquoi ? Parce que de plus en plus de gens recherchent des produits de santé naturels et que la protection de l'environnement est une préoccupation croissante. Cette évolution majeure implique que les fabricants d'emballages, notamment de flacons roll-on pour huiles essentielles, doivent concevoir des solutions innovantes, écologiques et pratiques. Ce rapport analyse en détail les recommandations stratégiques nécessaires pour définir des règles essentielles, intégrer de nouveaux matériaux, s'adapter aux tendances changeantes du marché et adopter des pratiques respectueuses de l'environnement. flacon roll-on d'huile essentielle qui fonctionnent maintenant et à l'avenir.

1. Introduction

Ce rapport explique en détail ce que signifie réellement un emballage « écologique ». Il présente les options intéressantes disponibles, comme le verre recyclé (verre post-consommation ou PCR) et le plastique recyclé (divers plastiques PCR). Il met en lumière les nouvelles opportunités du marché, recense les critères importants à prendre en compte lors du choix d'un fournisseur et prodigue des conseils pratiques. Ces conseils insistent sur le choix des matériaux appropriés, la conception d'objets réutilisables ou recyclables (économie circulaire) et la transparence envers les consommateurs. Des marques telles que… Vesseluxe nous sommes dans une position formidable, non seulement pour suivre le mouvement, mais aussi pour le mener, en nous orientant vers des emballages d'huiles essentielles plus durables.

2. Initiative mondiale en faveur du développement durable et des règles d'emballage

Les méthodes d'emballage des produits à travers le monde sont en pleine mutation. Ce changement s'explique par la demande croissante des consommateurs pour des options plus respectueuses de l'environnement et par la mise en place de réglementations strictes par les gouvernements.

2.1. Règlement de l’Union européenne sur les emballages et les déchets d’emballages (PPWR)

À compter du 12 août 2026, la réglementation européenne sur les emballages (PPWR) constituera une nouvelle loi majeure. Elle vise à prévenir les déchets d'emballages, encourage fortement la réutilisation et le recyclage, et lutte contre le suremballage. Ses principaux objectifs sont :

- Moins de déchets : L’objectif de cette réglementation est de réduire les déchets d’emballage de 5 à 15 % par personne entre 2030 et 2040. Cela indique clairement leur volonté de réduire l’impact environnemental.

- Emballage recyclable : Un élément essentiel du PPWR est l'obligation de recycler tous les emballages vendus dans l'Union européenne. Cela signifie que les emballages doivent être conçus de manière à ce qu'au moins 70 % d'entre eux soient recyclables d'ici 2030 et 80 % d'ici 2038. Des changements importants sont donc à prévoir dans leur conception.

- Contenu recyclé minimum : À compter du 1er janvier 2030, les emballages plastiques devront contenir entre 10 et 35 % de matériaux recyclés (PCR). Des règles strictes s'appliqueront également aux plastiques utilisés pour des produits alimentaires ou cosmétiques.

- Étiquettes plus petites et plus claires : La réglementation stipule clairement que l'emballage doit être aussi petit que possible, avec un espace vide maximal de 50 %. Elle exige également un étiquetage clair indiquant la nature de l'emballage et son mode de réutilisation, fournissant ainsi des informations utiles aux consommateurs.

- Restrictions : Le PPWR impose également des restrictions sur certains points, comme l'utilisation d'emballages de maquillage à usage unique dans les hôtels à partir de 2030. Il limite également l'utilisation de substances chimiques nocives appelées PFAS dans les emballages, ce qui contribue à protéger l'environnement et la santé des populations.

2.2. La loi SB 54 de Californie (Loi sur la prévention de la pollution plastique et la responsabilité des producteurs d'emballages)

La loi SB 54 de Californie, entrée en vigueur le 30 juin 2022, est une loi novatrice appelée Responsabilité attendue des producteurs (REP). Cette loi transfère la charge et les efforts liés à la lutte contre la pollution plastique des villes et des contribuables aux entreprises qui fabriquent des emballages plastiques. D'ici 2032, elle vise des objectifs ambitieux :

- Réduisez et recyclez : Une réduction de 25 % de l'utilisation du plastique, la garantie que tous les emballages soient 100 % recyclables ou compostables, et le recyclage de 65 % des emballages plastiques à usage unique : voilà ce qui va changer la donne.

- EPR et frais : Les entreprises d'emballage devraient adhérer à un organisme de responsabilité des fabricants (ORF) agréé par l'État. Cet organisme financera et gérera la collecte, le tri et le recyclage des déchets. Les cotisations versées à ces entreprises varieront en fonction du caractère écologique de leurs emballages, les incitant ainsi à privilégier les matériaux écologiques.

2.3. Programmes de responsabilité élargie des producteurs (REP) - Tendances mondiales

Les programmes de responsabilité élargie des producteurs (REP), qui rendent légalement les entreprises responsables de l'impact environnemental de leurs produits et emballages de leur conception à leur fin de vie, se généralisent rapidement à travers le monde. Ces programmes seront obligatoires au-delà de l'Union européenne d'ici fin 2024 et connaissent une forte croissance en Amérique du Nord (notamment au Canada et dans certains États américains) et en Asie-Pacifique. L'un des points communs de ces programmes est que les redevances varient en fonction du caractère écologique des emballages. Ainsi, les entreprises sont incitées à concevoir des emballages facilement recyclables, fabriqués à partir de matériaux recyclés ou réutilisables. Cela contribue à la création d'une économie circulaire où les biens et services sont utilisés de manière répétée.

2.4. Allégations « compostable » et « biodégradable » – Vérifications rigoureuses

Les gouvernements du monde entier examinent de près les allégations telles que « biodégradable » et « compostable ». Ils souhaitent empêcher les entreprises d'induire les consommateurs en erreur (écoblanchiment) et garantir la confiance des consommateurs dans leurs achats. Ces allégations doivent être parfaitement claires, scientifiquement prouvées et solidement étayées par des normes internationales spécifiques et reconnues. Par exemple, la norme EN 13432 définit les exigences relatives aux matériaux compostables industriellement. Elle impose la décomposition des matériaux dans certaines conditions et dans un délai déterminé. Il est essentiel que les marques indiquent clairement le type de décomposition (dans un composteur industriel, un tas de fumier ou l'océan) et le temps nécessaire. Un matériau compostable dans un environnement donné ne peut pas l'être dans un autre. Les allégations mensongères peuvent nuire gravement à la réputation d'une marque et entraîner de lourdes amendes.

Obtenez des échantillons gratuits

2.5. Règles spécifiques d'emballage des huiles essentielles/cosmétiques (UE)

Lorsque des huiles essentielles sont vendues pour un usage cutané ou en aromathérapie, elles doivent souvent se conformer à la réglementation européenne sur les produits cosmétiques (CE n° 1223/2009). Cette réglementation vise principalement à garantir la sécurité des produits, la transparence des ingrédients et la présence d'informations précises sur l'étiquette. De plus, si les huiles essentielles sont considérées comme dangereuses, elles doivent respecter des règles supplémentaires (telles que le règlement CLP). La nouvelle réglementation PPWR, qui interdit les emballages de maquillage à usage unique, notamment dans les hôtels, influence directement la conception des petits conditionnements d'huiles essentielles. Elle incite les marques à privilégier les emballages réutilisables ou rechargeables.

2.6. Plans d'emballage écologiques pour la région Asie-Pacifique

La région Asie-Pacifique (APAC) s'impose rapidement comme un chef de file en matière d'emballages écologiques. Cette évolution s'explique par la demande croissante des consommateurs pour des produits respectueux de l'environnement, la mise en place de réglementations strictes par les gouvernements et une prise de conscience accrue de la pollution plastique. Parmi les initiatives importantes, on peut citer celles de pays comme l'Inde, la Corée du Sud et l'Australie, qui ont rendu obligatoires les politiques de responsabilité élargie des producteurs (REP). Par ailleurs, on observe une multiplication des « pactes plastiques » et des engagements volontaires d'entreprises visant à réduire les déchets plastiques et à améliorer le recyclage.

3. Qu'est-ce qui rend les flacons roll-on d'huiles essentielles écologiques ?

En fait, pour savoir si l'huile essentielle flacon à bille Pour être écologiques, il faut connaître l'intégralité du processus, de la réception des matières premières à leur élimination.

3.1. Principales caractéristiques écologiques

- Biodégradabilité : Cela signifie qu'un matériau peut se décomposer naturellement en substances inoffensives telles que l'eau, le CO2 et les matières végétales, grâce à de petits organismes vivants, sans laisser de traces nocives.

- Recyclabilité :Il s'agit de la facilité et de l'efficacité avec lesquelles un matériau peut être collecté, traité et transformé en nouveaux produits. Cela permet d'éviter sa mise en décharge et de préserver les ressources naturelles.

- Rechargeable/Réutilisable :Les emballages réutilisables permettent de limiter l'utilisation de nouveaux ingrédients et de réduire les déchets. Cela inclut les systèmes de recyclage des bouteilles, ou leur renvoi pour nettoyage et réutilisation.

- Contenu recyclé post-consommation (PCR) :Il s'agit du contenu recyclé issu du recyclage de produits jetés par les consommateurs, intégré dans de nouveaux emballages. Ce procédé contribue à la création d'une économie circulaire et permet de réduire le nombre de marques utilisées.

- Empreinte carbone : Ce chiffre significatif indique la quantité totale de gaz à effet de serre (par exemple du CO2) émise tout au long du cycle de vie de l'emballage, depuis l'obtention du matériau et sa fabrication, jusqu'à son transport et enfin son élimination.

- Épuisement des ressources : Il semble que l'obtention et la fabrication de matériaux nécessitent des ressources naturelles limitées telles que le pétrole, les minéraux et l'eau.

- Production de déchets : Elle mesure tous les déchets créés durant le cycle de vie des emballages, et notamment la quantité qui est exclue de la décharge ou incinérée à partir de matériaux recyclés, de fumier ou réutilisée.

3.2. Comment nous mesurons l’impact environnemental (ACV et indicateurs clés de performance)

L'analyse du cycle de vie (ACV) est la méthode la plus fiable pour examiner l'impact environnemental d'un produit selon une approche normalisée (ISO 14040/14044), de sa conception à sa fin de vie (« du berceau à la tombe » ou « du berceau au berceau »). Pour les emballages d'huiles essentielles, les principaux indicateurs de performance (KPI) à mesurer sont généralement l'empreinte carbone (quantité de CO₂), la consommation d'énergie et d'eau, l'utilisation des ressources naturelles et la quantité de déchets produits. Des logiciels spécialisés tels que Simapro et Echinvent sont souvent utilisés pour l'ACV, exploitant d'importantes quantités de données environnementales. Cependant, il est difficile d'obtenir des informations précises et complètes auprès de tous les maillons de la chaîne d'approvisionnement mondiale. Généralement, les principaux problèmes environnementaux liés aux emballages surviennent lors de la production des matières premières (comme l'énergie nécessaire à la fusion du verre ou à la fabrication chimique du plastique) et lors de la mise au rebut des emballages, lorsque ceux-ci ne sont ni recyclés ni valorisés correctement.

4. Matériaux et idées de conception écologiques actuels

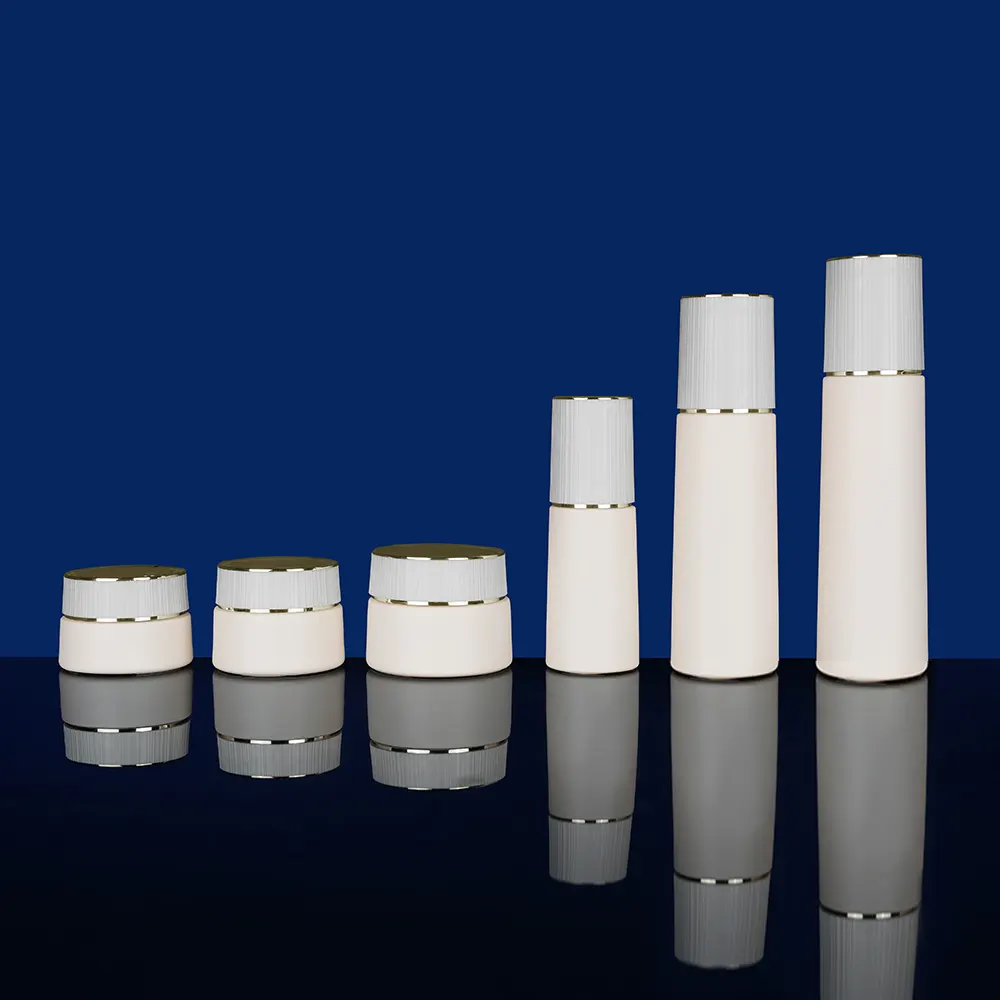

Les entreprises qui fabriquent des flacons roll-on d'huiles essentielles recherchent des matériaux écologiques et des designs innovants. Elles doivent trouver un équilibre entre le respect de l'environnement et la sécurité, l'efficacité et l'esthétique de leurs produits.

4.1. Emballages en verre : le meilleur choix, désormais avec des options recyclées

Le verre a toujours été un support de choix pour les huiles essentielles, car il ne réagit pas avec leur composition délicate. Le verre foncé (comme le verre ambré ou bleu) protège également les huiles des rayons UV, préservant ainsi leur efficacité. Le verre recyclé (verre PCR) est de plus en plus répandu, souvent composé à 70 % de matériaux recyclés. Cela réduit considérablement l'énergie nécessaire à sa fabrication et les émissions de CO2 par rapport à la production de verre neuf. Cependant, il est difficile de fabriquer du verre à partir de matériaux 100 % recyclés, car la quantité de verre recyclé de haute qualité disponible est parfois insuffisante. De plus, la fabrication du verre pour clous de pin reste énergivore, car sa fusion nécessite des températures élevées.

Obtenez des échantillons gratuits

4.2. Plastique recyclé (plastique PCR) : plus léger, moins de carbone, mais aspect potentiellement différent

Le plastique recyclé (plastique PCR) est une excellente option. Son impact environnemental est bien moindre que celui du plastique neuf, avec une réduction de 79 à 86 % des émissions de carbone. Disponible en différentes proportions de matériaux recyclés, un mélange de 30 à 60 % offre souvent le meilleur compromis entre performance et coût. Le plastique PCR, comme le PP (polypropylène) pour les bouchons et le PET (polyéthylène téréphtalate) pour les flacons, présente une excellente résistance aux produits chimiques, un atout majeur pour les huiles essentielles. Cependant, certains inconvénients subsistent : une apparence légèrement grise ou terne, de petites taches noires ou des irrégularités de couleur. Ces défauts peuvent poser problème pour les marques haut de gamme. De plus, la qualité variable du plastique recyclé peut compliquer son traitement. Le plastique recyclé utilisé dans le maquillage est généralement plus cher. Des réglementations telles que la loi AB 793 en Californie imposent des emballages plastiques à usage rapide, contenant une quantité minimale de matériaux recyclés, ce qui accélère leur utilisation.

4.3. Bouchons et billes en aluminium : résistants et recyclables

Les bouchons en aluminium sont parfaits car ils sont légers, très résistants et facilement recyclables, ce qui en fait un choix idéal pour les flacons roll-on d'huiles essentielles. La production d'aluminium neuf est très énergivore, contrairement à l'aluminium recyclé qui l'est beaucoup moins. Attention cependant : certaines huiles essentielles très acides ou réactives peuvent être incompatibles avec l'aluminium. Dans ce cas, un revêtement interne spécial ou un autre type d'aluminium peut s'avérer nécessaire. Les billes roll-on, indispensables pour l'application de l'huile, sont disponibles dans des matériaux robustes : l'acier inoxydable est très apprécié pour sa fluidité, sa propreté et son excellente étanchéité ; les billes en plastique sont économiques et légères ; enfin, le verre offre une sensation élégante et est insensible aux produits chimiques.

4.4. Concevoir pour la réutilisation : rechargeable et simple

Les marques adoptent de plus en plus le « design circulaire », basé sur la réutilisation. Les systèmes de recharge gagnent en popularité et constituent un moyen efficace de réduire les déchets à usage unique. Ces systèmes peuvent prendre différentes formes : bouteilles en verre renforcé et résistant, sachets de recharge légers en matériaux souples, ou encore fontaines à eau en magasin. Pour être performants, ces systèmes doivent être faciles d’utilisation, simples, parfaitement propres à remplir et, surtout, étanches. Parallèlement, les designs épurés, utilisant des matériaux simples et des formes simples, correspondent parfaitement à cette idée de robustesse et de durabilité. Ainsi, on utilise non seulement des matériaux de qualité, mais on conserve souvent une esthétique soignée et une fonctionnalité optimale, ce qui séduit les consommateurs.

5. Nouvelles idées et perspectives d'avenir en matière de technologies d'emballage durables

En réalité, la recherche continue de flacons roll-on d'huiles essentielles véritablement écologiques fait progresser les nouvelles idées et les méthodes avancées de création de matériaux et d'objets.

5.1. Technologies de recyclage avancées

Le recyclage avancé, également appelé recyclage chimique, représente une avancée majeure dans la gestion des déchets. Le recyclage classique se contente de trier et de fondre le plastique. Le recyclage avancé, quant à lui, décompose les plastiques mélangés, souillés ou difficiles à recycler en leurs éléments constitutifs (molécules). Des méthodes telles que la pyrolyse (chauffage en l'absence d'oxygène) et la dipolimation (décomposition du plastique en ses composants d'origine) permettent de créer de nouveaux matériaux plastiques. Ces derniers sont indiscernables des plastiques issus du pétrole, du gaz ou du charbon. Ils sont donc particulièrement adaptés à des applications exigeantes, comme l'emballage d'huiles essentielles, où une pureté et une fonctionnalité optimales sont indispensables. Malgré cela, ce procédé consomme généralement plus d'énergie et engendre des coûts plus élevés. Des études (analyse du cycle de vie, ou ACV) démontrent qu'il réduit considérablement les émissions de gaz à effet de serre par rapport à la production de plastique vierge à partir de combustibles fossiles. Le soutien accru des pouvoirs publics, notamment du Programme de recyclage des plastiques et des ressources naturelles (PPWR) de l'Union européenne, stimule la demande pour ces matériaux. Des systèmes de traçabilité spécifiques, tels que la certification ISCC Plus, sont essentiels pour garantir l'origine des matériaux recyclés et prouver leur présence dans le produit final. Ils apportent des informations fiables aux marques et aux consommateurs.

5.2. Plastiques biosourcés (polymères)

Les plastiques biosourcés sont fabriqués à partir de matières végétales plutôt que de pétrole, de gaz ou de charbon. Cette approche prometteuse permet de réduire notre dépendance aux produits chimiques issus des énergies fossiles. Parmi les exemples, on peut citer le PLA (à base d'acide polylactique, d'amidon de maïs ou de canne à sucre), le PEF (polyéthylène furanoate, à base de sucres végétaux) et le PHAS (polyhydroxyalaxines, produites par des bactéries). Le PLA, généralement issu d'amidon de maïs ou de canne à sucre, est très transparent et rigide, ce qui le rend adapté à la fabrication de certaines bouteilles. Le PEF, souvent issu de sucres végétaux, présente une excellente imperméabilité à l'oxygène et au CO2, ce qui contribue à prolonger la durée de vie des produits. Les PHAS, produits par des bactéries, sont particuliers car ils se décomposent facilement dans de nombreux milieux naturels, comme le sol et l'océan. Cependant, des défis importants subsistent : garantir leur compatibilité avec des huiles essentielles spécifiques et puissantes, assurer leur production à grande échelle, évaluer leur potentiel pour la fabrication d'engrais et de fumier à l'échelle industrielle, envisager l'utilisation de cultures pour leur production, et enfin, constater que leur coût est généralement supérieur à celui des plastiques classiques.

5.3. Matériaux à base de champignons (mycélium) et d'algues

Ces nouveaux matériaux à base de champignons (mycélium) et d'algues sont extrêmement écologiques et innovants. Ils sont actuellement parfaits pour l'emballage extérieur et peuvent également servir d'emballage principal. Le mycélium cultivé à partir de racines de champignons et de déchets agricoles (comme du cannabis ou des tiges de maïs) constitue une alternative révolutionnaire au polystyrène. Il offre d'excellentes propriétés d'amortissement et d'isolation, et permet même de produire du compost à domicile. Ces matériaux sont donc idéaux pour la fabrication d'inserts de protection ou de pièces sur mesure à l'intérieur des emballages d'huiles essentielles. Le plastique issu d'algues marines est étudié pour de nombreuses applications, notamment l'emballage alimentaire et les emballages intelligents. Ses avantages incluent son origine renouvelable, sa croissance rapide et sa biodégradabilité. Pour concurrencer les matériaux conventionnels, le mycélium et les algues marines doivent être moins chers. Le mycélium doit également présenter une meilleure résistance à l'humidité pour une utilisation plus large. En réalité, leur potentiel pour l'emballage circulaire (où tout est réutilisé) est immense et justifie des investissements et un développement constants.

Obtenez des échantillons gratuits

6. Analyse du marché et identification des opportunités

Les marchés des huiles essentielles et des emballages cosmétiques écologiques connaissent une croissance rapide, alimentée par l'évolution des goûts des consommateurs et le durcissement des réglementations gouvernementales.

6.1. Croissance du marché et raisons de cette croissance

Le marché des produits pétroliers, essentiel pour de nombreuses raisons, devrait croître de 37,25 milliards de dollars d'ici 2029. Parmi ces raisons, on note la demande croissante de produits naturels et biologiques, l'importance accrue accordée à la santé à l'échelle mondiale et une prise de conscience environnementale généralisée. Parallèlement, le marché des emballages cosmétiques écologiques connaît également une forte croissance. Ceci s'explique par la demande des consommateurs (plus de 50 % d'entre eux privilégient la stabilité lors de l'achat de produits de beauté), par une pression plus forte que la réglementation, et par les engagements pris par les marques en faveur de la protection de l'environnement.

6.2. Ce que les clients apprécient et ce qu'ils sont prêts à payer

Les consommateurs privilégient clairement les emballages durables. Plus de 60 % d'entre eux optent pour des emballages respectueux de l'environnement et sont prêts à payer environ 9,7 % de plus pour des produits écologiques à 74 %. Ils privilégient notamment le verre ou l'aluminium recyclés, les emballages à rupture naturelle et faciles à utiliser. Si la durabilité est un critère important, l'esthétique et la fonctionnalité restent tout aussi essentielles. Les consommateurs souhaitent que les emballages écologiques soient à la fois esthétiques et performants.

6.3. Différents groupes de clients

La génération Z et les Millennials sont les principaux groupes qui suivent les tendances en matière d'emballages durables. Les 18-24 ans (génération Z) sont prêts à payer plus cher pour 90 % des emballages durables, ce qui témoigne de leur forte sensibilité environnementale. Le pouvoir d'achat et l'influence de ce groupe augmentent rapidement, ce qui en fait une cible privilégiée. Par ailleurs, les ménages aisés sont toujours disposés à investir davantage dans des produits durables, ce qui signifie que les options écologiques peuvent être vendues plus cher sur certains segments du marché.

6.4. Différences à travers le monde

L'Europe domine actuellement le marché des huiles essentielles grâce à sa longue tradition en matière de remèdes naturels et à une réglementation stricte. L'Amérique du Nord, quant à elle, s'impose sur le marché des contenants d'huiles essentielles grâce à sa clientèle fidèle et à son industrie de l'emballage innovante. La région Asie-Pacifique (APAC) devrait connaître la croissance la plus rapide, tant pour les huiles essentielles que pour les emballages écologiques. Cette croissance s'explique par l'augmentation du pouvoir d'achat, l'essor de la classe moyenne, l'exode rural et la préférence des consommateurs, notamment en Chine, en Inde et en Asie du Sud-Est, pour les matériaux biologiques et naturels.

6.5. Le pouvoir des médias sociaux et les inquiétudes liées à l’écoblanchiment

Les réseaux sociaux ont transformé l'emballage en un outil puissant, un simple contenant influençant les décisions d'achat des consommateurs. Un emballage soigné et constamment repensé peut rencontrer un franc succès et diffuser largement le message d'une marque. Cependant, les consommateurs sont de plus en plus avertis et sensibles à l'écoblanchiment (lorsque les entreprises prétendent être respectueuses de l'environnement). Pour gagner la confiance des consommateurs, une marque doit faire preuve d'une totale transparence, expliquer clairement ses efforts en matière de développement durable et afficher fièrement des certifications fiables délivrées par des organismes reconnus (tels que USDA Organic, B Corp, FSC et Cradle to Cradle). Dans le monde numérique actuel, l'authenticité et la cohérence des engagements sont essentielles.

7. Comment choisir des fournisseurs de pièces durables

Collaborer avec les bons fournisseurs est essentiel pour la fabrication et la production à grande échelle de flacons roll-on d'huiles essentielles. De nombreux fournisseurs existent à travers le monde, notamment en Chine, où se concentrent de nombreux fabricants spécialisés. Ces derniers proposent une large gamme de composants, tels que des bouchons en aluminium de qualité, différents types de verre (dont du verre teinté bloquant les UV et du verre recyclé), ainsi qu'un nombre croissant d'options en plastique recyclé. Ils fournissent également des billes roll-on (en acier inoxydable, en plastique ou en verre) et d'autres pièces détachées. Souvent, les fournisseurs de ce secteur offrent des solutions de personnalisation complètes et proposent un service « clé en main » simplifiant ainsi l'approvisionnement des marques.

7.1. Comment vérifier efficacement les fournisseurs

Pour garantir un contrôle efficace et complet des fournisseurs, il est indispensable d'aller au-delà du simple coût et de la qualité. Il convient également d'évaluer leurs performances environnementales, sociales et de gouvernance (ESG), leur efficacité et leur solidité financière.

A. Performance environnementale :

- Matériau certifié : Choisissez des fournisseurs qui proposent des matériaux certifiés pour leur décomposition naturelle, fabriqués à partir de sources renouvelables et utilisant une grande quantité de matériaux recyclés.

- Réduction de l'empreinte carbone : Vérifiez ce que le fournisseur a fait et a prouvé en matière de réduction de votre empreinte carbone (ses émissions totales de gaz à effet de serre), par exemple en utilisant une faible consommation d'énergie et en passant aux énergies renouvelables.

- Efficacité des ressources : Observez leur consommation d'eau, leurs programmes de réduction des déchets et la manière dont ils s'approvisionnent en matières premières de façon responsable.

- Gestion des déchets : Pour gérer les déchets, consultez leurs plans complets, qui précisent les quantités recyclées et la manière dont ils éliminent correctement les déchets dangereux.

- Certification ISO 14001 : Regardez ce certificat international (ISO 14001) qui prouve qu'ils disposent de bons systèmes de gestion environnementale.

- Intégrité du produit : Veillez à ce que les matériaux d'emballage préservent la qualité des huiles essentielles en effectuant des tests rigoureux pour les dégrader ou les empêcher de se salir.

B. Responsabilité sociale :

- Pratiques de travail éthiques : Vérifiez qu'ils respectent les réglementations internationales du travail, versent des salaires corrects, offrent un lieu de travail sûr et n'ont pas recours au travail des enfants ou au travail forcé (par exemple, certificat SA8000).

- Engagement communautaire : Découvrez comment le fournisseur aide les communautés locales.

- Approvisionnement responsable : Veillez à ce que les matières premières soient obtenues de manière équitable et respectueuse de l'environnement, évitez les « minerais de conflit » et la déforestation.

C. Gouvernance (Mode de fonctionnement) :

- Transparence: Demandez des informations claires sur leurs opérations, leurs chaînes d'approvisionnement et leurs rapports ESG.

- Reporting ESG audible : Recherchez des rapports ESG réguliers vérifiés par des experts indépendants.

- Conformité réglementaire : Vérifiez qu'ils respectent scrupuleusement les règles environnementales, de travail et d'emballage (par exemple, REP, Guide vert de la FTC, Access).

- Gestion efficace de la chaîne d'approvisionnement : Vérifiez si le fournisseur est capable de gérer le risque, d'assurer le bon déroulement des opérations et de maintenir la qualité de sa chaîne d'approvisionnement.

D. Certificat d'autres groupes :

- Clé pour prouver les affirmations : FSC (One Stewardship Council) pour le papier/bois dans les certifications importantes, RCS (norme relative aux matériaux recyclés) pour le contenu en PCR, TNV Austria (pour les engrais), BPI (Bio-Digradable Products Institute), Cradle to Kraddle (pour la conception circulaire), ISO 14001 (B. Corp Corporel et B Corp Corporel et B. Corp Corporel et B. Corp Corporel prouvent que leurs affirmations de stabilité sont réelles.

E. Nouvelles technologies et idées :

- Investissement dans la recherche : Vérifiez si le fournisseur investit dans la recherche et le développement de méthodes pour créer de nouveaux matériaux et objets durables.

- Traitement avancé : Recherchez leur capacité à utiliser des techniques de recyclage avancées, à fabriquer du plastique d'origine végétale ou à utiliser d'autres techniques novatrices.

- Outils numériques : Vérifiez s'ils utilisent des outils numériques tels que la blockchain pour permettre un meilleur suivi de leur chaîne d'approvisionnement et de leurs contrats intelligents, afin d'optimiser leur fonctionnement.

- Conseils d'experts : Les meilleurs fournisseurs proposent souvent non seulement des produits, mais aussi des conseils spécialisés, des informations sur le marché et une aide à la résolution des problèmes.

F. stabilité financière :

- Long terme et développement : Vérifiez la santé financière, les performances antérieures et le développement du fournisseur afin de vous assurer qu'il peut être un partenaire à long terme.

- Solutions permettant de réduire les coûts : Vérifiez s'ils proposent des prix compétitifs et des solutions innovantes permettant de réaliser des économies tout au long du cycle de vie du produit.

- Analyse du marché : Recherchez des fournisseurs capables de vous fournir des informations utiles sur les nouvelles tendances, les matériaux disponibles et les changements de réglementation.

Obtenez des échantillons gratuits

8. Conseils avisés et comment développer des produits

Les marques qui aspirent à devenir leaders des flacons roll-on d'huiles essentielles écologiques doivent être intègres, transparentes et constamment innovantes. Elles doivent intégrer le développement durable à chaque étape de la conception et de la commercialisation de leurs produits.

8.1. Choix des matériaux et conception

- Mettre l'accent sur la réutilisation : Pour l'emballage principal, privilégiez un verre recyclé foncé de haute qualité (verre PCR) contenant 40 à 70 % de matériaux recyclés. Il protège le produit et préserve l'environnement. Pour le bouchon et les autres pièces en plastique, utilisez un plastique recyclé de bonne qualité (PP ou PET PCR) contenant 30 à 60 % de matériaux recyclés. Envisagez des couleurs opaques et opaques pour masquer les éventuelles imperfections d'aspect parfois rencontrées avec le plastique recyclé. L'aluminium est une option pour les bouchons, mais attention aux huiles essentielles qu'il peut contenir. Veillez à utiliser un revêtement intérieur adapté si nécessaire.

- Rendez-le rechargeable et réutilisable : Concevoir un emballage principal robuste et esthétique, réutilisable à l'infini. Mettre en place un système de recharge simple et propre, comme une simple pochette de recharge ou des stations de recharge en magasin. Veiller à la conception précise des pièces essentielles, telles que le corps et le capuchon du stylo à bille, afin d'éviter les fuites ; envisager des systèmes spécifiques, comme le système Springlock™, pour une sécurité accrue.

- Explorer de nouvelles idées (possibilités futures) :Surveillez de près les nouveaux plastiques biosourcés (PLA, PEF, PHA) afin d'identifier les applications les plus pertinentes. Privilégiez les matériaux issus de déchets ou de plantes non alimentaires pour éviter toute concurrence avec l'alimentation. Explorez de nouveaux ingrédients, tels que les emballages externes (inserts de protection, par exemple) ou même les emballages principaux à base de champignons (mycélium) ou de composites d'algues marines. Assurez-vous de leur résistance aux produits chimiques et de leur stabilité après des tests rigoureux. L'utilisation de matériaux recyclés de haute qualité (PCR) passe par des partenariats stratégiques avec des entreprises de recyclage de pointe. Vérifiez que ces matériaux possèdent des certifications solides attestant de leur contenu recyclé.

- Conception simple et monomatériau :Simplifiez les conceptions pour utiliser moins de matériaux. Cela réduit la consommation de ressources et facilite la fabrication. Essayez d'utiliser un seul type de matériau autant que possible. Cela simplifie le tri pour le recyclage et améliore le recyclage de l'ensemble du système de flacons à bille.

8.2. Comment se positionner et parler aux clients

- Soyez honnête et montrez vos certifications :Expliquez clairement et honnêtement aux clients les caractéristiques permanentes de l'emballage. Affichez clairement les certifications fiables d'organismes tiers (FSC, RCS, TNV, BPI, B Corp, etc.) sur l'emballage et les publicités. Cela renforce la confiance et confirme vos affirmations. Utilisez le code QR sur l'emballage pour fournir aux clients des informations détaillées : composition du produit, analyse du cycle de vie (ACV) et instructions précises pour son recyclage.

- Former les clients : Ne vous contentez pas d'affirmer ; au contraire, informez vos clients des avantages environnementaux de leur choix, expliquez-leur comment les systèmes rechargeables peuvent leur faire économiser de l'argent et fournissez-leur des instructions claires et faciles pour remplir, réutiliser et jeter correctement les emballages.

- Utilisez les réseaux sociaux : Partagez votre expérience de marque sur les réseaux sociaux, en mettant en avant vos nouveaux emballages durables et attrayants ainsi que vos engagements environnementaux. Vous créerez ainsi des liens et fidéliserez une clientèle soucieuse de l'environnement.

- Privilégiez le haut de gamme : Veillez à ce que l'utilisation d'emballages écologiques ne dévalorise pas le produit ni n'en altère l'efficacité. Un emballage durable doit conserver une allure haut de gamme et offrir une expérience utilisateur optimale, reflétant parfaitement la qualité perçue des huiles essentielles.

8.3. Collaboration avec les fournisseurs et gestion de la chaîne d'approvisionnement

- Contrôles stricts des fournisseurs : Mettez en place un système complet de vérification des fournisseurs, axé sur leurs performances ESG. Assurez-vous, par des contrôles et des évaluations réguliers, qu'ils respectent les règles et s'améliorent constamment.

- Exigez l'honnêteté :Les fournisseurs fournissent des données complètes sur leur impact environnemental (analyse du cycle de vie), leur consommation d'énergie, leurs émissions de gaz à effet de serre et la quantité de déchets qu'ils produisent. Ils exigent également qu'ils cartographient la provenance des matières premières et vérifient scrupuleusement leurs pratiques d'approvisionnement éthiques.

- Partenaire pour les nouvelles idées : Collaborer étroitement avec les fournisseurs qui investissent dans de nouveaux matériaux durables et des technologies de pointe telles que le recyclage avancé, le plastique d'origine végétale et la blockchain pour le suivi.

- Réduire les risques liés à la chaîne d'approvisionnement :Diversifiez vos fournisseurs afin de ne pas dépendre d'un seul. Prévoyez des solutions de repli solides en cas de problème, comme une pénurie de matériaux durables.

8.4. Perspectives et projets d'avenir

Une étude détaillée du coût du cycle de vie (CCV) permettra de comprendre pleinement l'étude et de démontrer les gains financiers à long terme et le retour sur investissement des projets d'emballage permanent. Il convient d'examiner la faisabilité et les avantages de la fabrication locale de matériaux et de composants d'emballage d'origine végétale. Cela permettra de réduire la pollution liée au transport et de dynamiser les économies locales. Il est important d'explorer les techniques d'emballage intelligent (par exemple, les étiquettes RFID/NFC) pour un meilleur suivi des produits, l'amélioration du recyclage et la fidélisation des clients. Des recherches sur les plastiques d'origine végétale ou recyclables de manière avancée, en particulier pour les pièces des rouleaux, sont nécessaires afin de créer une économie circulaire complète (réutilisation/recyclage infini). Il est essentiel de promouvoir l'utilisation de nouveaux matériaux durables, conformément aux normes de l'industrie, pour de meilleures pratiques de recyclage et des centres de valorisation des déchets performants.

En suivant scrupuleusement ces conseils, les marques peuvent non seulement répondre à la demande croissante de flacons roll-on d'huiles essentielles écologiques, émanant des consommateurs et des gouvernements, mais aussi devenir des leaders incontestés de l'innovation continue. Ceci permettra d'instaurer une relation de confiance durable, de fidéliser la clientèle et de garantir un avenir prometteur sur le marché.

Commentaires

Catégories de produits

Bouteilles en promotion

Pourquoi le flacon de parfum en forme d'ours gagne-t-il en popularité ?

Un adorable flacon de parfum en forme d'ours, idéal pour personnaliser vos emballages, cadeaux ou collections. Un design charmant qui apporte une touche ludique et originale à votre marque.

Tirer parti d'une conception innovante de flacons compte-gouttes pour se différencier sur le marché

Découvrez comment la conception innovante des flacons compte-gouttes, les matériaux durables et les technologies intelligentes stimulent

Étude de cas : Flacons roll-on personnalisés pour une marque allemande d’huiles essentielles

Étude de cas de flacons à bille personnalisés avec une marque allemande d'huiles essentielles, prenant en charge la vente en gros, les marques privées et les commandes groupées B2B.

L'art et la science derrière les fabricants de flacons de parfum personnalisés

Découvrez comment les fabricants de flacons de parfum personnalisés gèrent la conception et l'ingénierie des moules

Choisir le bon fournisseur de flacons compte-gouttes en verre : pourquoi le prix compte plus que tout.

Apprenez à choisir le bon fournisseur de flacons compte-gouttes en verre en privilégiant la qualité, la conformité, la stabilité de l'approvisionnement et la durabilité plutôt que le simple coût.

- +86 186 5178 1159

- [email protected]

- Mon-Sun 07:00-21:00

Étiquettes

Étude de cas : Des problèmes de distribution de flacons roll-on en verre à un approvisionnement stable en usine

Des problèmes rencontrés par un fournisseur de flacons à bille en verre ont conduit une usine pétrolière espagnole à se tourner vers nous pour obtenir des flacons à bille sur mesure étanches, d'une qualité stable et disponibles en grande quantité.

Flacons compte-gouttes en verre sur mesure ou standard ? Guide d’achat pour les revendeurs

Vous cherchez un fournisseur de flacons compte-gouttes en verre ? Consultez notre guide sur les emballages personnalisés et standards. Découvrez comment nous aidons les acheteurs à optimiser leurs coûts et l’impact de leur marque.

Étude de cas : Flacons de parfum en verre personnalisés pour un studio de parfumerie de niche français

Des flacons de parfum en verre personnalisés ont été livrés pour un studio de parfumerie français. Nous avons fourni des flacons dépolis à effet dégradé avec des bouchons en bois, renforçant ainsi l'image de marque et son attrait en point de vente.

L’avantage stratégique d’un partenariat avec un grossiste de flacons roll-on en verre pour les marques de beauté haut de gamme

Découvrez comment un grossiste leader de flacons roll-on en verre propose des emballages personnalisés, durables et de haute qualité, offrant une protection optimale de la formule et une conformité aux normes internationales.